Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

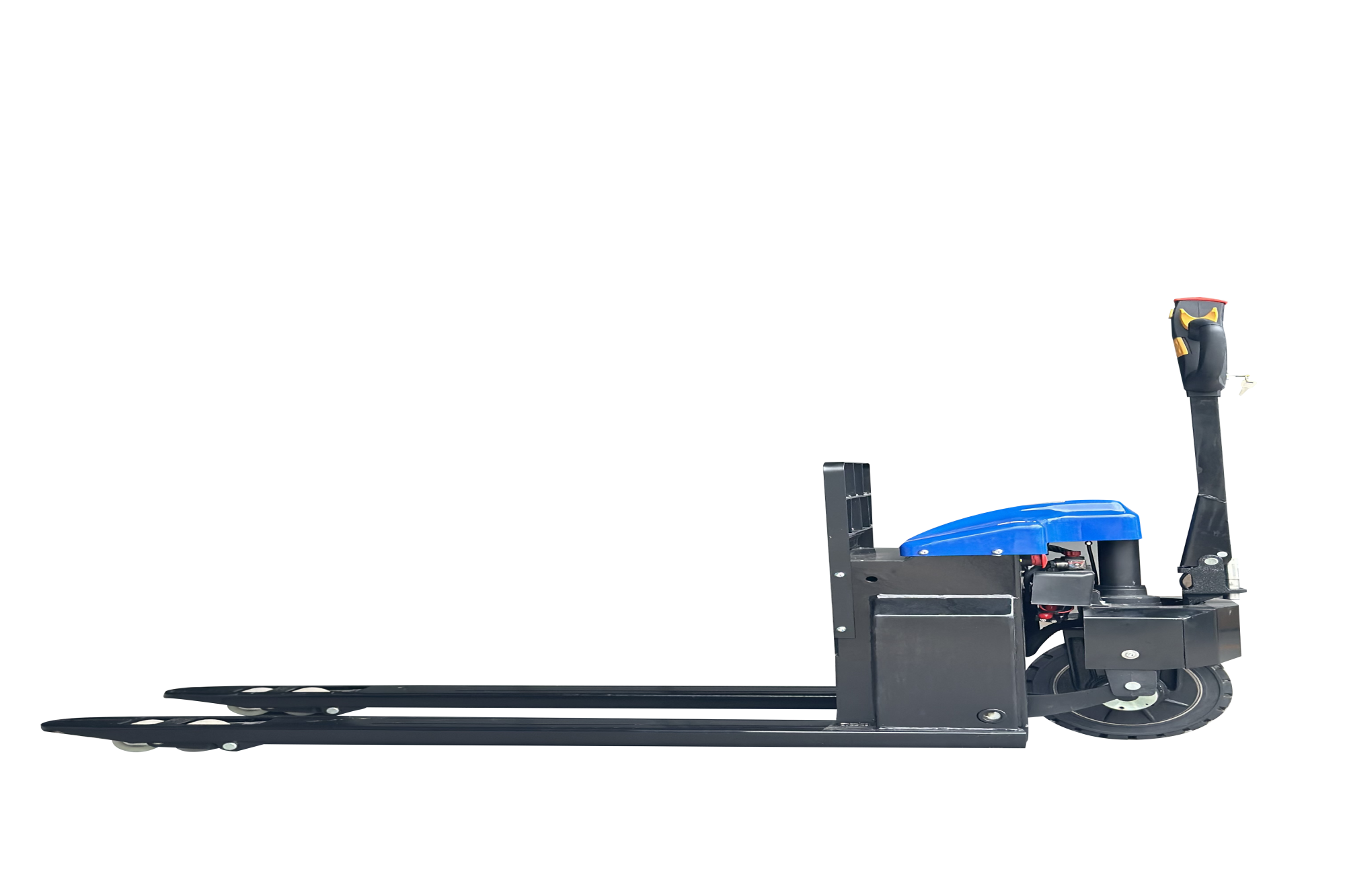

What is the Electric Pallet Jacks/Truck

The electric pallet jacks/truck is a compact and lightweight industrial vehicle commonly used both domestically and internationally, with a significant market potential. It operates on a battery-powered DC motor, featuring a hydraulic lift station and a centralized control joystick for easy operation. Designed for standing driving, this electric pallet jacks/truck offers convenient, stable, and fast operation. Its small size and flexible maneuverability make it suitable for various environments, including shopping malls, supermarkets, warehouses, goods yards, and workshops. It is particularly well-suited for industries such as food, textile, and printing, thanks to its low noise, low pollution, and efficient operation. The electric pallet jacks/truck is equipped with specially designed rubber/polyurethane wheels for the driving, load, and balance wheels, ensuring a longer lifespan. Its ultra-compact design enables it to navigate narrow passages effortlessly, while its high-speed performance and strong load capacity enhance efficiency. Additionally, it features an imported step-less speed regulation computer system and a large-capacity traction battery for optimal performance.

Features of Electric Pallet Jacks/Truck

To ensure the safety of individuals, the electric pallet jacks/truck incorporates a delayed acceleration function. When the operator accelerates and rotates the handle to the maximum speed, this unique feature automatically activates. It gradually increases the speed from low to high within a span of 3-8 seconds, preventing sudden acceleration that may cause harm.

Additionally, the handle serves as a power-off brake mechanism. When in an upright position, the handle is used for braking. During operation, the handle is pressed down to engage the brake. Furthermore, when the handle is pressed to the bottom, the brake is also activated. This allows the operator to brake even when transporting heavy loads on slopes, preventing the vehicle from freely sliding downhill and minimizing accidents.

The electric pallet jacks/truck boasts a five-point structure, which enhances its stability. This unique design is particularly effective on slippery surfaces or slopes, allowing the vehicle to maintain better stability and functionality.

Electric Pallet Jacks/Truck manufacturers | wholesale Electric Pallet Truck

electric pallet jacks/truck have a wide range of applications and are primarily utilized for transporting heavy loads. They are commonly found in warehouses and factories, but their versatility also allows them to be used in diverse settings such as hospitals and retail stores. These trucks are manufactured by various companies, ensuring a wide selection for potential buyers. Many manufacturers even offer wholesale discounts on electric pallet jacks/truck, making them more accessible and affordable for businesses.

China Electric Pallet Jacks/Truck manufacturers, suppliers, factory - Kinlift Forklifts trucks

Kinlift Forklifts trucks, a renowned manufacturer and supplier of electric pallet jacks/truck in China, offers top-quality products and excellent service to its customers. With a productive factory and company, we are committed to delivering reliable and durable electric pallet jacks/truck at competitive prices. Our extensive range of electric pallet jacks/truck caters to various industries including warehouses, food & beverage factories, and distribution centers. Choose Kinlift for dependable electric pallet jacks/truck that meet your specific needs.