Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

What is the Electric Reach Forklift

Electric reach forklift is a kind of industrial handling vehicles and warehouse forklifts. It refers to a forward wheeled handling vehicle for loading and unloading, stacking and short-distance transportation of pallet goods. It is used for the transportation of large items in storage, and is usually driven by batteries. The electric reach forklift combines the advantages of a counterbalanced electric forklift and a stacker. It has the characteristics of environmental protection and energy saving, low noise, high lifting, and small working space.

Characterstics of Electric Reach Forklift

The electric reach forklift has a small lifting weight and is often driven by an electric motor. Electric electric reach forklift has the characteristics of maneuverability and flexibility, light operation, no pollution, and low noise.

Electric reach forklift has the common characteristics of counterbalanced forklift and electric stacker. When the mast reaches the front end, the center of gravity of the load falls on the outside of the fulcrum, which is equivalent to a counterbalanced forklift; when the mast is fully retracted, the center of gravity of the load falls on the inner side of the fulcrum, which is equivalent to an electric stacker. The combination of these two performances gives this forklift the advantages of operational flexibility and high load. At the same time, the volume and dead weight will not increase a lot, saving working space to the greatest extent and greatly improving the utilization rate of warehouse space.

Precautions for the use of electric reach forklifts

When using the electric reach forklift, special attention should be paid to timely charging and correct maintenance of the battery. Pay attention to the method when charging the battery, not only make the battery fully charged, but also not cause the battery to overcharge.

In the electric reach forklift operation, try to minimize the use of long-term and long-distance acceleration. When the vehicle starts and the speed increases, stabilize the accelerator pedal. If the road condition is better, the vehicle will continue to accelerate. When the vehicle needs to decelerate, relax the accelerator pedal and lightly depress the brake pedal, so that the energy of deceleration can be fully utilized. If the vehicle has a regenerative braking function, the kinetic energy during deceleration can be recovered. When the vehicle is going down a slope, do not disconnect the circuit that drives the motor, and gently step on the brake pedal to make the vehicle run in a regenerative braking state, and use the kinetic energy of the vehicle down to reduce the energy consumption of the battery.

China Electric Reach Forklift manufacturers, suppliers, factory - Kinlift Forklifts trucks

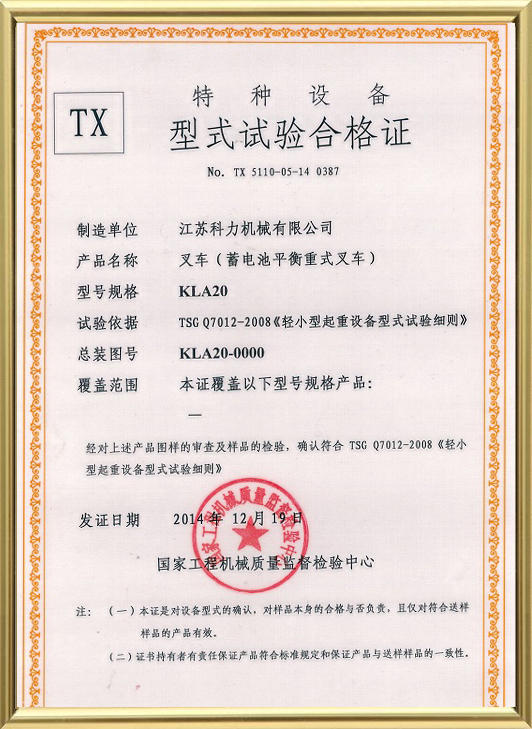

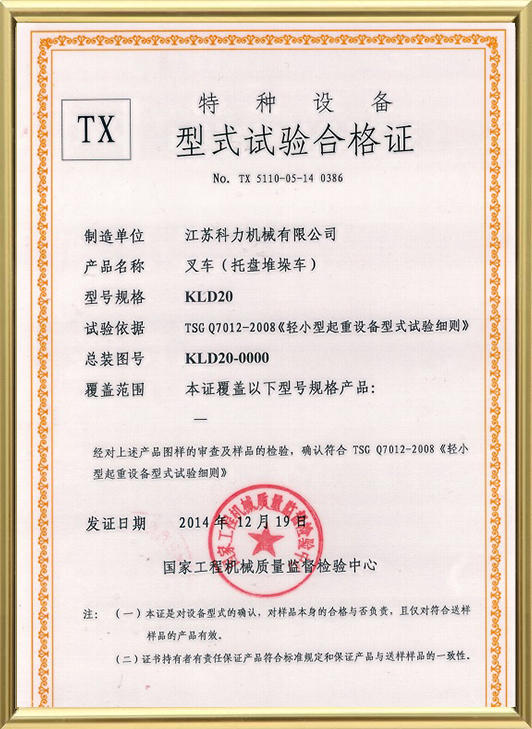

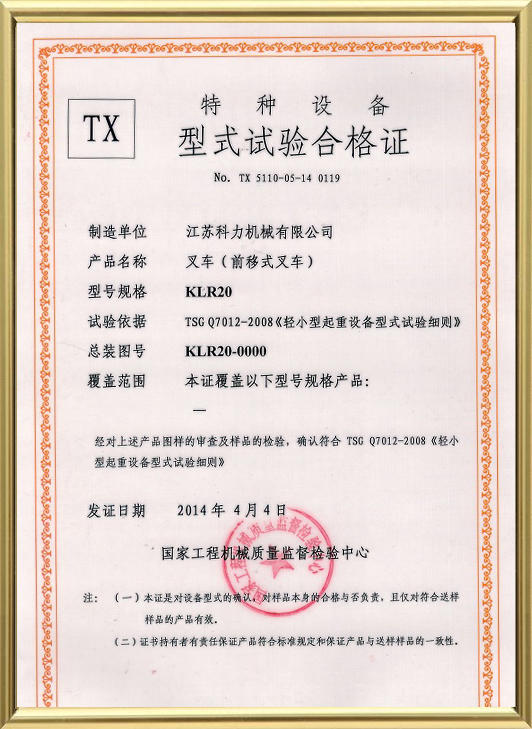

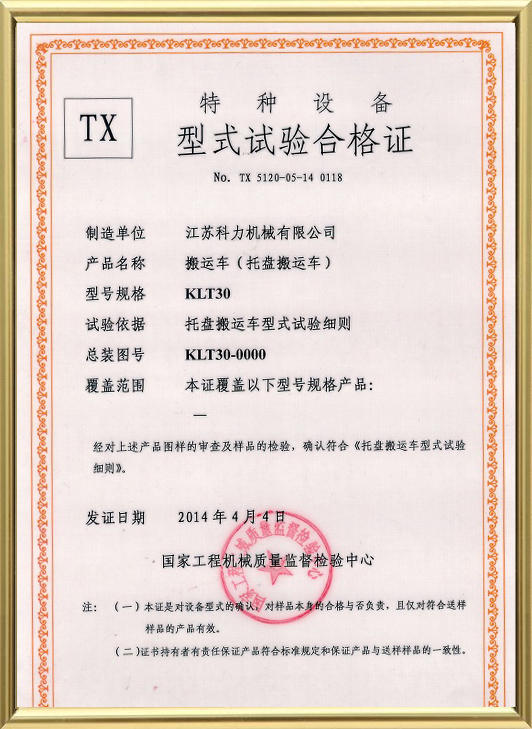

A reach forklift is a type of forklift that has an extendable boom that allows the operator to move materials horizontally and vertically. These forklifts are commonly used in warehouses and distribution centers to load and unload trucks. Kinlift is one of the leading manufacturers of electric reach forklifts in China. We offer a wide range of forklifts with different load capacities and lifting heights to meet the needs of our customers.

Chinese Forklift Manufacturers

Chinese Forklift Manufacturers have been a major contributor to the international forklift industry for many years. With such a long and rich history, Chinese Forklift Manufacturers have become experts in their field. They are renowned for their state of the art designs, innovative engineering, and quality craftsmanship. As one of the largest manufacturers of forklifts in the world, Chinese Forklift Manufacturers utilize their vast resources and expertise to produce exceptional products that satisfy customers’ needs around the globe.

In today's highly competitive business environment, logistics efficiency is directly related to the ...

Read More +In the field of logistics and warehousing that pursues efficiency and safety, the KLR-C Series 1.5T-...

Read More +In the context of global advocacy of green and sustainable development, the logistics industry is ac...

Read More +Electric walkie stacker: the future star of smart warehousing Driven by the wave of digitalization a...

Read More +Load Capacity in Pallet Stackers: 1.Definition and Importance: Definition: Load capacity refers to t...

Read More +Applications of Tow Tractors: 1.Material Handling in Warehouses and Distribution Centers: Goods Tran...

Read More +