Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Product Profile of Fully Electric Counterbalanced Forklift:

1. Type of counterbalanced forklift without baselegs, applicable to single-faced and double-faced pallet.

2. EPS turning system, with handlebar steering

3. Design of lightweight short-wheelbase, specially applicable to building floor’s operation and short-distance stacking.

4. Horizontal drive, drive wheel can be able-dismantled and quite convenient to replace it.

5. Mast additionally installed precise side rolling wheel that functions guidance with less friction, effectively boosts the stability of forklift mast.

6. Chinese standard 1244 plate chain, safer for lifting operation.

Wholesale electric counterbalanced forklifts

If you are looking for electric forklifts at wholesale prices, there are a few things you should know. First, electric forklifts are powered by batteries, so you'll need to factor in the cost of batteries and charging stations. Second, electric forklifts tend to be more expensive than their gasoline-powered counterparts. However, they are also more environmentally friendly and have lower maintenance costs. Finally, make sure to compare different models and brands before making a purchase.

Electric Counterbalance Forklifts Manufacturers - Kinlift

Electric forklifts are an essential piece of equipment in many warehouses and factories. They are used to move heavy loads of inventory and materials around the facility. Electric forklifts are powered by batteries, which makes them more environmentally friendly than gas-powered forklifts. When shopping for an electric forklift, it is important to consider the lifting capacity,fork length, and battery life. Kinlift is a leading manufacturer of electric counterbalance forklifts.

An electric forklift is a type of powered industrial truck that is used to lift and move heavy loads. These forklifts are powered by batteries, which makes them environmentally friendly and very efficient. There are many different manufacturers of electric forklifts, but Kinlift is one of the leading suppliers in the world. Their electric counterbalance forklifts are some of the best in the business, and they offer a wide variety of models to suit any need.

China Forklift Manufacturer - Kinlift

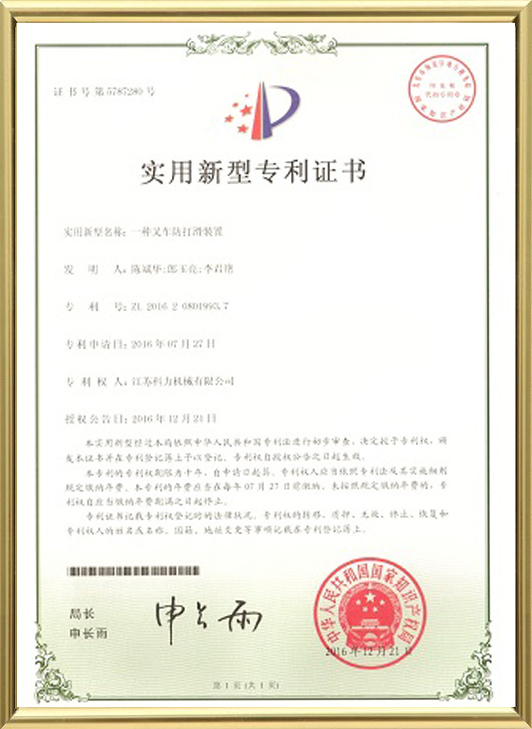

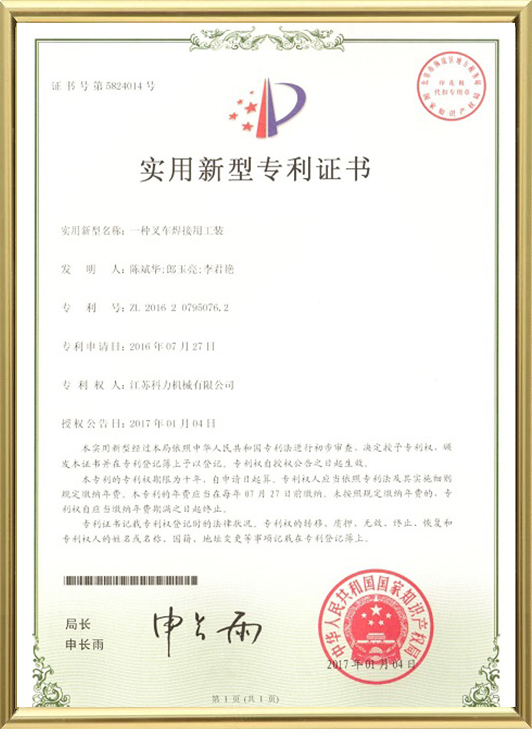

Kinlift is one of the leading China forklift manufacturers in the world, providing a wide range of products from electric forklifts, pallet stackers and order pickers to reach trucks and more. Kinlift has established itself as a reliable supplier for customers across many industries, offering excellent quality products at competitive prices. The company's extensive network of suppliers ensures its products are built using the latest technology and manufactured to the highest standards.

Electric reach forklifts are crucial for modern warehousing and industrial operations. These machine...

Read More +Electric reach forklifts are essential tools in modern logistics operations, providing efficient and...

Read More +In the modern warehouse environment, storage capacity while maintaining efficient material handling ...

Read More +Electric forklifts, particularly electric reach forklifts, have become increasingly popular in moder...

Read More +In the world of warehouse logistics and material handling, choosing the right type of pallet truck c...

Read More +Introduction Electric counterbalance forklifts are widely used in a variety of industries, offering ...

Read More +