Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

Quick View

An electric pallet stacker is a device that lifts and lowers pallets. They are commonly used in warehouses and factories to move heavy loads of goods or materials. Electric pallet stackers come in a variety of sizes and lifting capacities to suit different business needs. They can be operated by a single person, making them a convenient and efficient way to move heavy loads around a warehouse or factory floor.

The electric pallet stacker is suitable for narrow aisles and limited space operations. It is an ideal tool for loading, unloading and stacking goods in high-bay warehouses, supermarkets, workshops. The machine adopts computer program control, stepless speed change, high quality C-shaped steel refined wide field of view mast, the maximum lifting height of 0.5T load can be up to 5.2 meters, the maximum lifting height of 1T load can be up to 4.5 meters, the maximum lifting height of 2T load can be up to 3 meters. Batteries can be loaded and unloaded from three directions and can be equipped with random pedals for the operator. The all-electric stacker has a simple structure, flexible control and good micro-motion.

Advantages of Electric Pallet Stacker

An electric pallet stacker is a great addition to any warehouse or business that needs to move heavy pallets of goods.

The machine is easy to operate and can easily lift and move pallets weighing up to 2,000 pounds.

The electric stacker is also very versatile and can be used to move other heavy objects such as barrels and crates.

The stacker also comes with a built-in charger so you can keep it charged at all times.

Electric pallet stackers are a must for any business that needs to move heavy loads on a regular basis.

Application of Electric pallet stackers

Electric pallet stackers can be widely used in petroleum, chemical, pharmaceutical, textile, military, paint, pigment, coal and other industries, as well as ports, railways, freight yards, warehouses and other places containing explosive mixtures for loading, unloading, stacking and transportation Operation. With the operation of electric pallet stackers, it can greatly improve work efficiency, reduce labor intensity of workers, and win market competition opportunities for enterprises.

Electric pallet stackers are mainly used in storage and short-distance transportation of pallets and goods on shelves in warehouses and yards. The sturdy forklift special mast (three-stage mast), imported electric control and hydraulic units, low mouth noise, No pollution, low failure rate, international classic style, can be designed according to customer requirements.

About the battery life and boot time of the fully electric pallet stacker

The fully electric pallet stacker is designed to tackle both long-term and short-term storage needs - bigger, bulkier objects can be easily moved with the machine's floor-level access and its powerful battery system. This fully electric stacker has proven to have a longer-than-average battery life, going up to 8 hours without needing recharging, meaning long shifts are no problem.

Boot time is also faster than similar models, as the fully electric pallet stacker can go from sleep mode to full operation in less than 8 seconds. This makes it extremely productive and efficient when transitioning between tasks quickly.

Wholesale Electric Pallet Stacker manufacturers - Kinlift Forklifts trucks

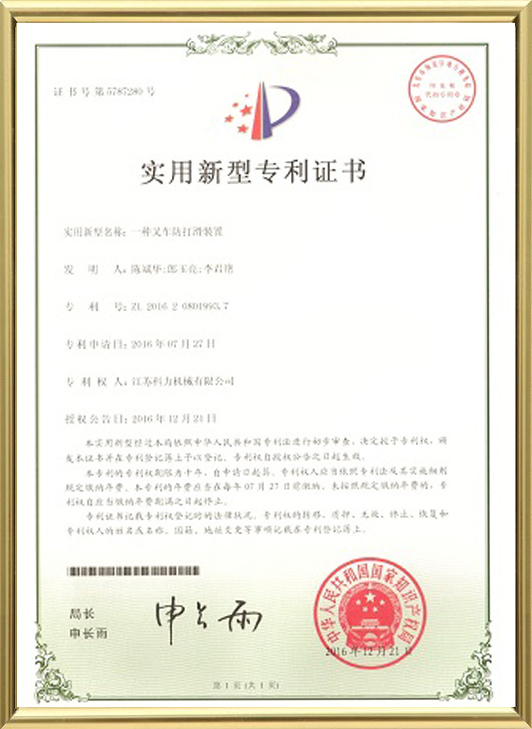

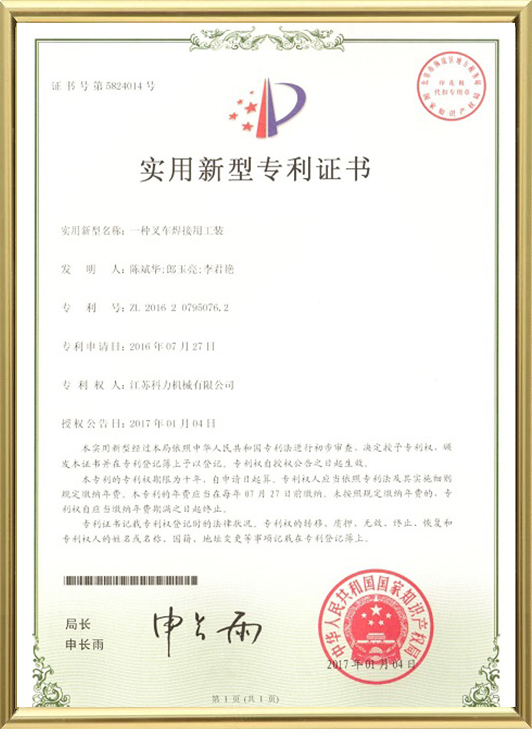

A leading manufacturer of electric pallet stackers is Kinlift. The company offers a wide range of products to meet the needs of different customers. Its products are available at wholesale prices. Some of the features of Kinlift's products include: high quality, durability, and low noise levels.

Chinese Forklift Brands

The Chinese forklift industry has grown rapidly in recent years, offering a wide variety of brands to choose from. Whether you're looking for efficient and reliable equipment for your construction site or warehouse, there are many great Chinese forklift brands to consider. From large companies offering international service to smaller, locally-operated companies, these brands offer a wide selection of models and features that you can customize for your specific needs.

China Electric Pallet Stacker Manufacturers, Suppliers, Factory

Electric Pallet Stacker Manufacturer, Supplier, Factory - We are an Electric Pallet Stacker manufacturer and supplier in China. Our products are sold well in many countries and regions, such as the United States, Canada, Australia, Japan and so on. We have a wide range of products including electric pallet stacker cranes, manual pallet stacker cranes, hydraulic pallet stacker cranes and so on. If you are interested in our products, please contact us.

In the world of warehouse logistics and material handling, choosing the right type of pallet truck c...

Read More +Introduction Electric counterbalance forklifts are widely used in a variety of industries, offering ...

Read More +Introduction As modern warehouses continue to evolve toward higher efficiency, automation, and susta...

Read More +Introduction Electric counterbalance forklifts are crucial in various industries due to their effici...

Read More +As warehouse operations continue to evolve toward higher density storage, greater efficiency, and lo...

Read More +In modern industrial environments, forklifts are indispensable machines that help streamline operati...

Read More +